About our Snowmaking System

Since 1966 when Diamond Peak was the first resort in the Tahoe region to invest in a snowmaking system, we've been committed to providing our skiers and snowboarders the best snow surface possible. Thanks to the consistent and pure water supply available courtesy of the IVGID Public Works Department, Diamond Peak's snowmaking system has consistently allowed the resort to enhance what Mother Nature provides and extend the ski season.

Diamond Peak Ski Resort purchased four new TechnoAlpin TR8 high-efficiency snowmaking guns for the 2021-22 ski season. In addition, Diamond Peak will be testing one of TechnoAlpin’s latest TT10 tower fan guns on the slopes this winter, bringing the newest snowmaking technology to the resort where snowmaking began in the Lake Tahoe Basin. The addition of these new snow guns will allow Diamond Peak to increase the probability of opening the ski area earlier and with top-to-bottom terrain, even during winters in which the resort is reliant on 100% man-made snow during the early season.

Diamond Peak Ski Resort purchased four new TechnoAlpin TR8 high-efficiency snowmaking guns for the 2021-22 ski season. In addition, Diamond Peak will be testing one of TechnoAlpin’s latest TT10 tower fan guns on the slopes this winter, bringing the newest snowmaking technology to the resort where snowmaking began in the Lake Tahoe Basin. The addition of these new snow guns will allow Diamond Peak to increase the probability of opening the ski area earlier and with top-to-bottom terrain, even during winters in which the resort is reliant on 100% man-made snow during the early season.

TechnoAlpin’s TT10 tower fan gun utilizes advanced nozzle valve technology to ensure optimum energy efficiency and resource conservation during snowmaking operations, while the air cooling system ensures unsurpassed snow output and quality. TechnoAlpin’s portable TR8 snow gun is designed to require less maintenance and produce more man-made snow per hour, even during marginal snowmaking conditions. The design of the TR8 snow guns requires just one electric motor to power the entire machine, making the units more reliable, more efficient, and less noisy than previous models of snow guns.

The new TT10 and TR8 snow guns also come equipped with TechoAlpin’s latest ATASSplus software system, which optimizes snowmaking based on weather conditions and forecasted snow needs. ATASSplus makes energy-efficient snowmaking much easier, and the software is able to communicate directly with Diamond Peak’s SNOWsat grooming management software (courtesy of PistenBully), which can provide the snowmaking system with real-time information on snow depths based on Diamond Peak’s snowcat grooming fleet.

The four additional TechnoAlpin TR8 snow guns augment the four TR8s Diamond Peak purchased before the 2019-20 season, and add to Diamond Peak’s snowmaking system of 14 additional fan guns, HKD high-efficiency snowmaking towers and compressed air-water snowmaking guns, which collectively cover 75% of the developed terrain at Diamond Peak Ski Resort.

About our SNOWsat Technology

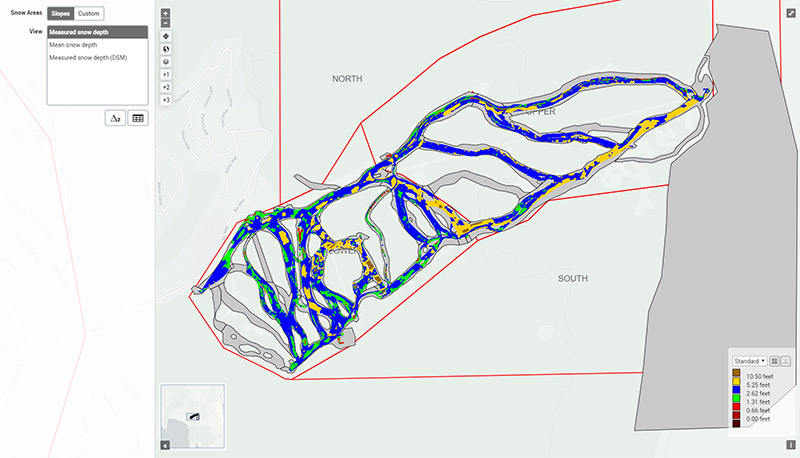

Diamond Peak's grooming machines are equipped with Pistenbully's SNOWsat snow depth monitoring technology, allowing our grooming operators to see real-time snow depth information on the slopes as they groom. This data allows our grooming team to ensure an ideal snow surface for skiing and riding, even during lean snow years. (The image above shows the snow depths on the slopes as of Feb. 20, 2020. Our slope maintenance team strives to maintain green or deeper snow depths to ensure a quality snow surface, and will actively push snow from areas of abundance to leaner areas when needed.) The SNOWsat system also tracks all aspects of our snow cats' operations including run time, gas consumption, GPS tracking on the mountain, and service maintenance, which allows our managers to optimize grooming routes for greater efficiency. Click here for more information on how SNOWsat works...

About our Grooming Fleet

New for the 2021-22 season, Diamond Peak will debut a brand new snowcat/groomer. The resort’s new PistenBully 600 Park grooming machine incorporates all of the latest grooming and shaping technology that PistenBully has to offer, in a comfortable package that reduces emissions, increases efficiency, and provides Diamond Peak’s award-winning slope maintenance staff with even more tools to lay down perfect corduroy all over the mountain.

The 600 Park model comes equipped with terrain park specific features that will come into play in the Village Terrain Park and throughout the resort including the Child Ski Center learning area and beginner learning zones. The 600 Park also features PistenBully’s newest diesel engine technology which reduces noise, fuel consumption and particulate emissions (by up to 66% compared to prior models), while delivering increased torque and power.

According to Mountain Operations Manager Jay Rydd, “The ParkPro is a machine that was designed around the needs of terrain parks, but its enhanced features and ergonomics make every task on the mountain easier. Diamond Peak already had a few ParkPro groommers, so adding another just multiplies what we are able to do every night.”

All of the groomers in Diamond Peak’s fleet also include PistenBully’s SNOWsat snow depth monitoring system, which allows the resort’s snow surfaces team to more accurately monitor snow depths on the ski runs and see where additional snowmaking is needed throughout the season. The SNOWsat system also tracks all aspects of Diamond Peak’s snowcats operations including run time, diesel consumption, GPS tracking on the mountain, and service maintenance, and communicates directly with the new TechnoAlpin snow guns when applicable.

We currently have five grooming machines, all PistenBully. Four of the machines are the Park Pro models which give us the ability to shape our terrain parks and tricky slope sections better than ever.